Transformer monitoring system

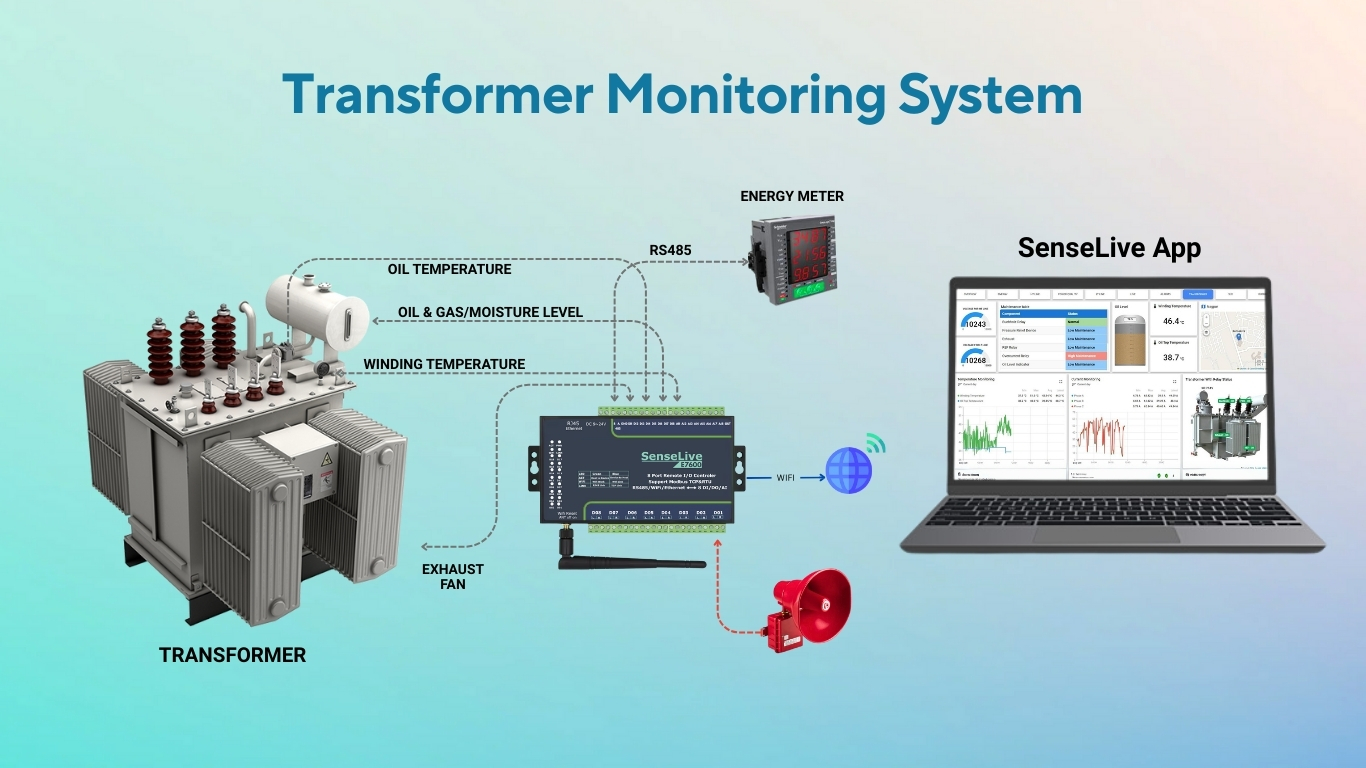

The SenseLive A Transformer Monitoring System is a combination of hardware sensors, communication modules, and software platforms designed to continuously track the health, performance, and operating conditions of a transformer performance .Its primary goal is to detect potential issues early, prevent failures, extend equipment lifespan, and optimize performance".

Key Features

Fault Detection

Detects internal faults like partial discharge, overheating, and overcurrent; provides maintenance alerts, breakdown analysis, and trend reports.

Health Index

Aggregates multiple parameters such as temperature, load cycles, and oil quality to compute a comprehensive transformer health index.

Real-Time Parameter Monitoring

Continuously monitors critical transformer parameters (temperature, voltage, load, oil level, etc.) for instant insights and alerts.

Gas & Oil Quality Monitoring

Detects oil degradation, contamination, and dissolved gas anomalies for early maintenance and reliability improvement.

Overview

The SenseLive Transformer Monitoring System is an advanced Industrial IoT solution designed for continuous, real-time monitoring of a transformer’s health, performance, and operating conditions. Aimed at detecting potential issues early, preventing failures, extending equipment lifespan, and optimizing performance, it combines intelligent sensors, communication modules, and a centralized monitoring platform to deliver actionable insights. The system tracks key electrical, thermal, and mechanical parameters, integrates seamlessly with SCADA systems and cloud dashboards, and enables proactive maintenance for industrial, commercial, and utility-scale transformer installations.

Complete Feature Set

Real-Time Transformer Health Monitoring

Continuously tracks transformer electrical, thermal, and mechanical parameters to detect abnormalities early.

Comprehensive Oil & Gas Quality Analysis

Monitors oil level, moisture content, and dissolved gas analysis (DGA) to assess insulation and detect internal faults.

Thermal & Load Management

Tracks winding and oil temperatures, load currents, and voltage to prevent overloading and optimize performance.

SCADA & Cloud Integration

Seamless integration with SCADA systems and cloud dashboards for real-time remote monitoring and analytics.

Predictive Maintenance & Fault Diagnostics

Uses trend analysis of temperature, vibration, and DGA data to schedule maintenance and predict failures before they occur.

Components Used

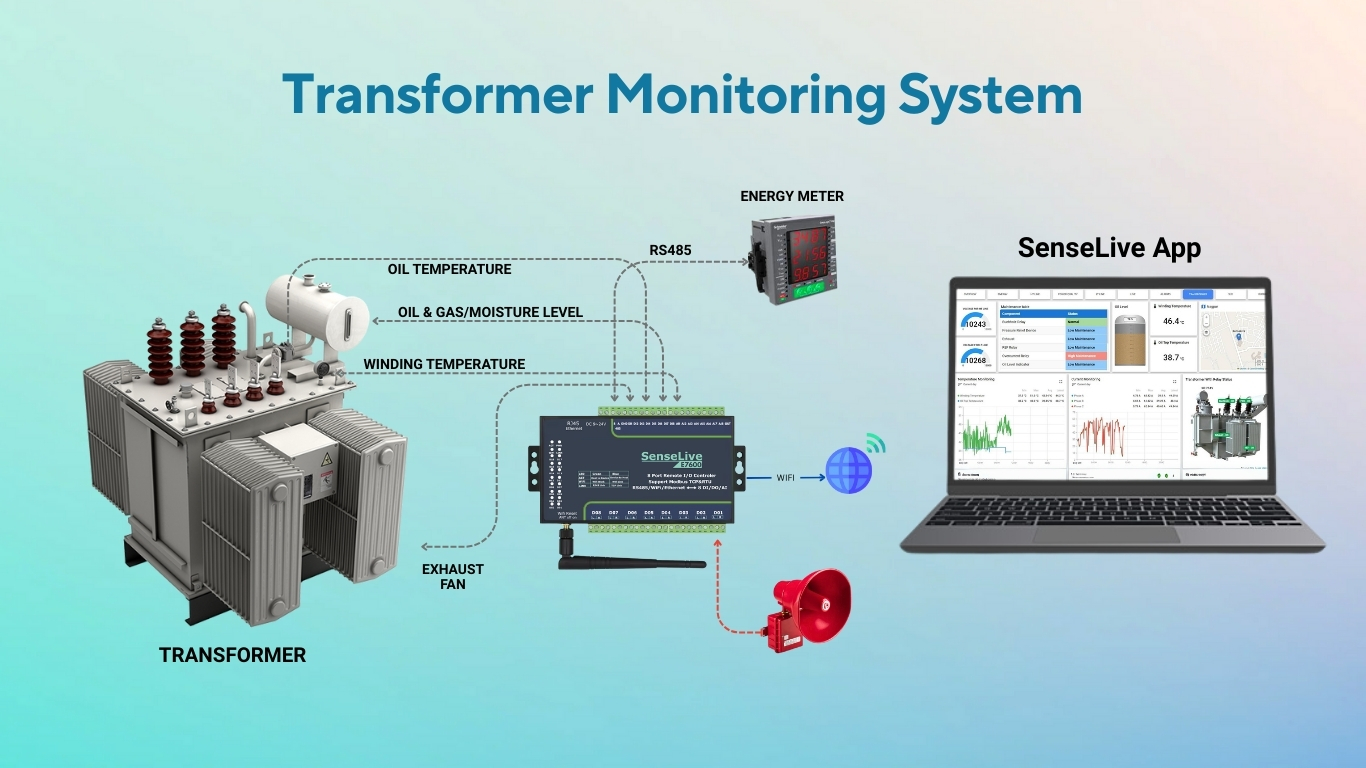

SenseLive Edge8000

Wireless Bus Bar Temperature Monitoring System

- Wireless temperature monitoring

- Integrated energy metering

- Dual relays for control

- Real-time alerts and notifications

SenseBT-222

Battery-Powered Wireless Temperature Sensor

- Long Battery Life

- Wide Range

- Industrial Design

- Wireless Communication

SenseCT-222

CT-Powered Wireless Temperature Sensor

- Self-Powered

- Real-time Monitoring

- Easy Installation

- Maintenance-Free

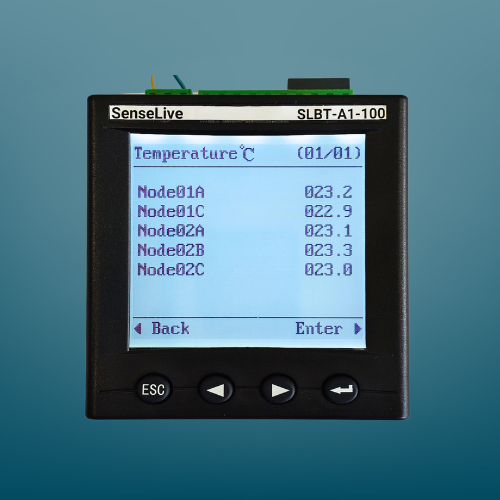

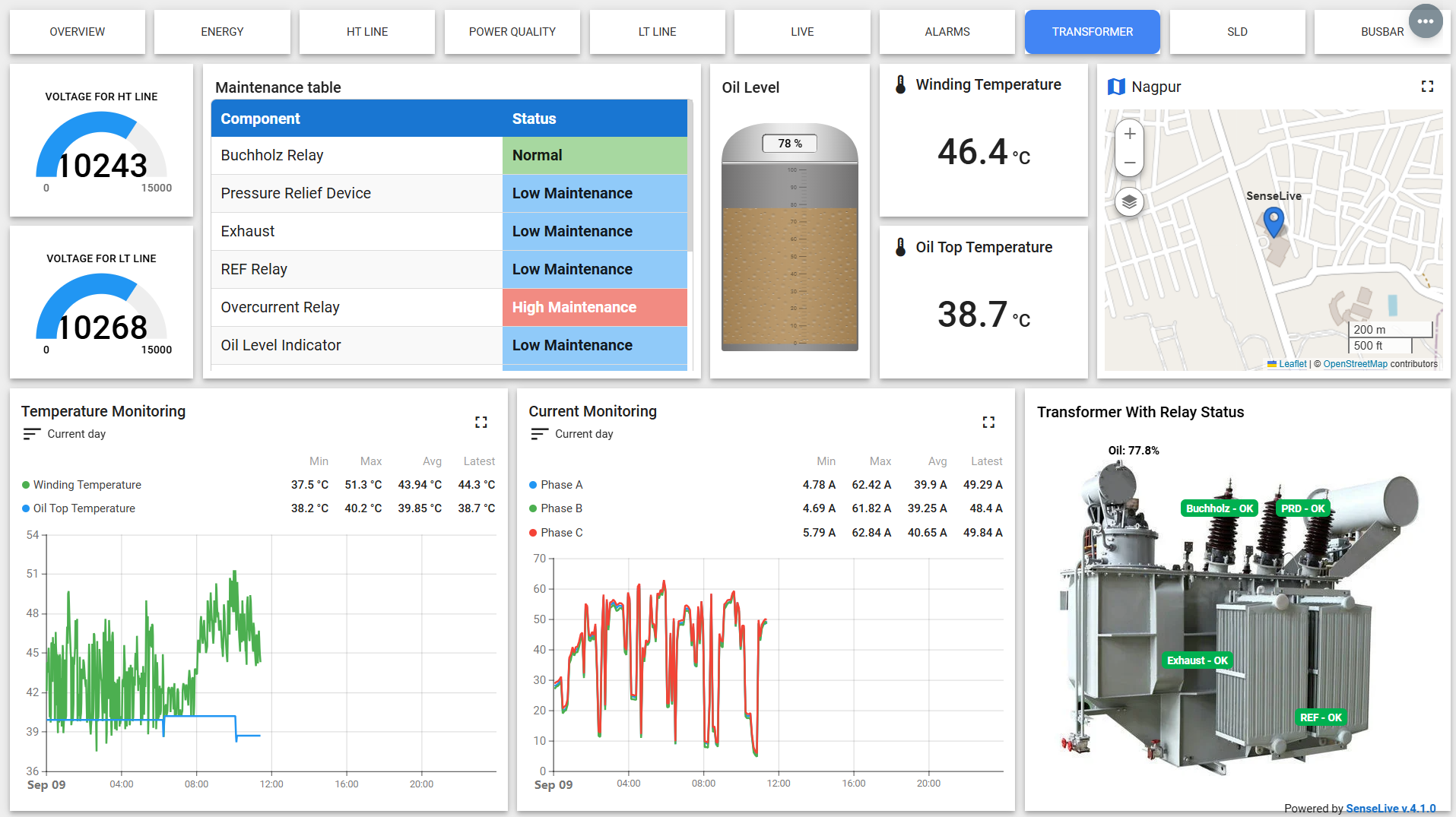

Dashboard Description

Gain actionable insights with the SenseLive transformer-condition-monitoring-system. Critical relay status inputs from the transformer are continuously captured and displayed locally, and can be integrated into your SCADA or cloud platforms for real-time health monitoring, alarms, trip events, and comprehensive reporting.

This enables proactive management of your electrical assets.

Complete Feature Set

- Buchholz Relay – Alarm & Trip for internal gas accumulation / major faults

- Oil Temperature Relay (OTI) – Alarm & Trip for unsafe oil temperature

- Winding Temperature Relay (WTI) – Alarm & Trip for winding hot-spot overheating

- Pressure Relief Device (PRD) – Trip on rapid internal pressure rise

- Oil Level Relay – Alarm for low oil level / possible leakage

- Cooling System Status – Fan / pump running and failure alarms

- Differential Protection Relay (87T) – Trip for internal winding faults

- Overcurrent Relay (50/51) – Trip on overload or short-circuit conditions

- Restricted Earth Fault (REF) Relay – Trip on winding-to-earth faults

- Historical status logging for trend analysis and predictive maintenance

Key Applications

Oil Temperature Monitoring

Continuously track transformer oil temperature to prevent insulation breakdown and overheating faults.

Load & Current Monitoring

Monitor load currents in real-time to prevent overloading and ensure optimal transformer operation.

Buchholz Relay Alerts

Detect internal gas accumulation or sudden oil movements to identify slow or major internal faults early.

Winding Temperature Measurement

Track winding temperatures to prevent insulation degradation and improve transformer lifespan.

Cooling System Supervision

Monitor fans and oil pumps in transformer cooling systems to ensure efficient heat dissipation.

Tap Changer Health Monitoring

Track OLTC (On-Load Tap Changer) operation and temperature to prevent mechanical and electrical failures.